Generator maintenance can be quite difficult to understand, especially when there are some issues that you don’t understand or know about. One such challenge is wet stacking. This is super common and the most misunderstood problem. Along with this, it affects diesel generators and can also impact their performance and lifespan on a large scale.

What is Wet Slacking?

It happens when a diesel generator runs without sufficient load for a long period of time. The term ‘wet slacking’ visually describes what happens – unburned fuel gets collected in the exhaust system. This creates a black, oily substance that can leak from the exhaust stack. That’s why the name ‘wet’ slacking.

This develops when the diesel engines work below their ideal temperature, which prevents complete fuel combustion. Modern diesel generators are designed to run at 75-80% of their rated capacity. When it is working below 40% continuously, the engine is not able to reach proper temperature, and this ends up in incomplete combustion.

Related: What Happens If You Don’t Maintain Your Generator?

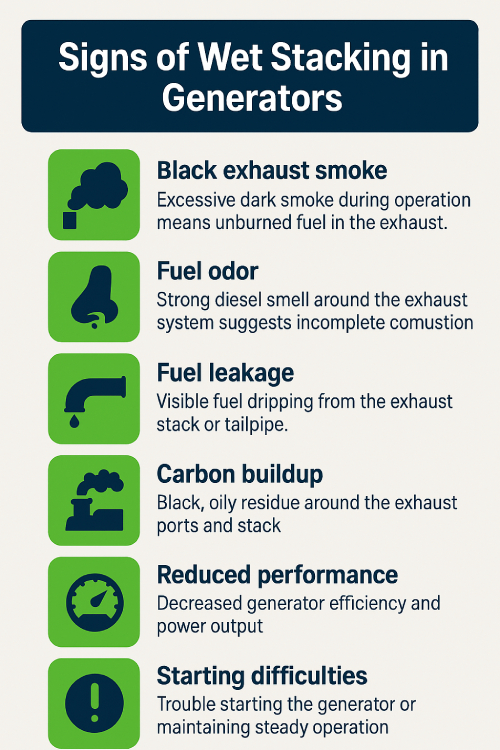

Signs of Wet Stacking in Generators

Identifying wet slacking early can prevent a lot of serious damage. Look for these warning signs:

- Black exhaust smoke: Excessive dark smoke during operation means unburned fuel in the exhaust.

- Furl odor: Strong diesel smell around the exhaust system suggests incomplete combustion.

- Fuel leakage: Visible fuel dripping from the exhaust stack or tailpipe.

- Carbon buildup: Back, oily residue around the exhaust ports and stack.

- Reduced performance: Decreased generator efficiency and power output.

- Starting difficulties: Trouble starting the generator or maintaining steady operation.

These symptoms can develop gradually, making regular inspection important for early detection. The severity mostly correlates to how long and how frequently the generator has been running under light load conditions.

Why Wet Stacking Occurs?

Understanding the unknown causes helps prevent wet stacking. There are a lot of factors that contribute to this condition:

Insufficient Load

The main reason for wet stacking is continuously running generators below recommended load levels. Without enough load, engines cannot reach ideal working temperatures (around 175- 195°F or 80- 90 °C) and prevent complete fuel combustion.

Modern diesel generators work best when they use 75-80% of their capacity. When they usually work below 40%, the risk of wet stacking increases by a lot.

Oversized Generator Units

Facilities usually install generators with capacities that go beyond their actual needs. While this provides a safety margin, there are also possibilities for wet stacking. When a 500 kW generator regularly powers a 100 one load, it works at just 20% capacity, which is below the recommended range.

Improper Maintenance

Neglected maintenance contributes to wet stacking:

- Clogged fuel injectors spray fuel badly, which also leads to incomplete combustion.

- Dirty air filters block the airflow and disrupt the fuel-air mixture.

- Worn piston rings and cylinder walls reduce compression. This affects combustion efficiency.

- Faulty engine timing throws off the precise combustion sequence.

Environmental Factors

Weather and operating environment play unexpected roles:

- Cold temperature makes it hard for engines to reach their best working temperature.

- Alteration of air-fuel ratio, due to increase in humidity, can also negatively impact the efficiency of combustion.

- High altitude reduces air density, changing the combustion process.

The Impact of Wet Stacking on Generator Performance

Wet stacking is not an inconvenience but actually progressively damages the generator systems.

Short-term Effects

At the start, wet stacking causes:

- Power Output Reduction: Reduce generating capacity because of inefficient combustion.

- Increased Fuel Consumption: More fuel is used from the same power output.

- Exhaust System Contamination: Buildup of unburned fuel and carbon deposits.

- Environmental Compliance Issues: Increased emissions exceeding regulatory limits.

Long-term Consequences

Without intervention, serious problems can develop:

- Cylinder Wall Glazing: Hard carbon deposits can end up forming on cylinder walls that reduce compression.

- Fuel injector damage: Clogging and premature wear from fuel residue.

- Turbocharger Failure: Carbon buildup on turbocharger parts.

- Exhaust System Corrosion: Acidic compounds from unburned fuel eat away at the metal parts.

- Increased Maintenance Costs: More frequent repairs and part replacements.

- Shortened Generator Lifespan: Overall decrease in working life expectancy.

Environmental and Compliance Concerns

Wet stacking increases emissions, which could breach the local air quality regulations. The black smoke is a particulate matter containing emission, which includes unburnt hydrocarbons, and other pollutants that can incur undercover regulatory fines and negatively impact the ecosystem.

Related: How Much Electricity Does AC Units Use? A Comprehensive Comparison

Preventing Wet Stacking in Diesel Generators

Proactive measures can prevent wet stacking and increase generator life. Implement these strategies for best performance:

Proper Sizing and Load Management

- Right-size your generator: Install a unit that matches your actual power requirements.

- Implement load banks: Use resistive loads to regularly add artificial load when real-world demands are low.

- Develop load management protocols: Create schedules for generators that run at higher loads for shorter periods rather than light loads for longer times.

Regular Load Testing

- Monthly Load Testing: Run generators at 75-80% capacity for at least 30 minutes monthly.

- Annual Full-Load Testing: Perform yearly tests at full capacity to clean out carbon buildup.

- Document Performance Metrics: Track parameters like exhaust temperature, fuel consumption, and power output to spot trends.

Maintenance Practices

- Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules.

- Clean Fuel Injectors Regularly: Make sure of proper fuel atomization for combustion.

- Replace Air Filters: Maintain proper airflow for best air-fuel mixture.

- Check Exhaust Systems: Check for carbon buildup and clean as needed.

- Monitor Engine Timing: Verify correct timing for proper combustion sequence.

Advanced Solutions

- Install Automatic Exercisers: Program regular operation at ideal loads.

- Consider Parallel Generator Setups: Use multiple smaller units instead of one oversized generator.

- Explore Modern Fuel Addictive’s: Some of these additives improve combustion efficiency and reduce carbon buildup.

- Upgrade to load-sensing controllers: Automatically adjusts operation based on demand.

Remedying Existing Wet Stacking Issues

If your generator already shows signs of this process, then you should take these actions:

Immediate Steps

- Run at Higher Load: Turn the generator at 75-80% capacity for several hours.

- Inspect Exhaust System: Clean the collected carbon deposits and check for damage.

- Change Oil and Filters: Remove contaminated oil that might have fuel and carbon particles.

- Check Injectors: Clean or replace the clogged fuel injectors.

Professional Intervention

Severe wet stacking might need professional service:

- Cylinder Head Removal: Clean carbon deposits from combustion chambers.

- Compression Testing: Evaluate cylinder condition and compression ratios.

- Turbocharger Inspection: Check for damage from carbon buildup.

- Exhaust System Evaluation: Assess structural integrity and replace rusted parts.

Recovery Monitoring

After remedy:

-

- Track Performance Metrics: Monitor the operation to make sure the issue is solved.

- Implement Regular Testing: Establish an ongoing load testing schedule.

- Review Operating Procedures: Adjust protocols to prevent recurrence.

When to Call in the Professionals

Although some maintenance can be handled in-house, some situations need expert intervention.

- Persistent symptoms despite basic remediation

- Significant power output reduction

- Unusual noises or vibrations

- Visible mechanical damage

- Critical installations where downtime is not an option

Professional technicians can do specialized diagnostics and repairs beyond typical maintenance capabilities.

Cost Implications of Wet Stacking

The financial impact goes beyond repair costs:

- Increased Fuel Consumption: 10-15% higher fuel use because of inefficient combustion.

- Premature Part Replacement: Components like injectors and turbochargers fail earlier.

- Higher Maintenance Frequency: More service calls and labour costs.

- Downtime Expenses: Lost productivity during unplanned outages.

- Shortened Equipment Lifespan: Earlier replacement of the entire generator unit.

Preventive measures usually cost far less than addressing systemic damage. Regular load testing and maintenance might add minimal operational costs but can save thousands in repairs and replacement.

Related: How To Connect a Generator To Your House Without a Transfer Switch?

Conclusion

Wet stacking is a significant yet preventable challenge for diesel generator operators. By understanding its causes, recognizing early warning signs, and implementing preventive measures, you can extend generator life and make sure of reliable performance when the power is needed most.

Regular maintenance, proper sizing, and appropriate loading schedules form the foundation of wet stacking prevention. For existing generators, remedy might need professional service, but the investment pays dividends through improved reliability and increased equipment life.

Remember that diesel generators are designed to work under load. Generators, like any high-performance engine, operate best when utilized how they are designed to be. Provided adequate maintenance and proper use, a generator is capable of giving reliable emergency power for many years. For more such information – contact Ferezco Power System.